ทำไมต้องเอลจี้ รุ่น อีจี?

ที่สุดด้านการใช้พลังงานอย่างมีประสิทธิภาพ

ค่าใช้จ่ายในการซ่อมบำรุงและดำเนินการที่ต่ำที่สุดในระดับเดียวกัน

การทิ้งน้ำมันตกค้างที่ต่ำที่สุด

ที่สุดด้านการรับประกัน

ความน่าเชื่อถือที่โดดเด่นอันเนื่องมาจากอัตราความเร็วรอบในการทำงานต่ำและอุณหภูมิในการทำงานต่ำ

ข้อมูลการดำเนินงานและมาตรการความปลอดภัย

อุปกรณ์ควบคุมความเร็วรอบมอเตอร์ทางเลือกเพื่อการใช้พลังงานที่มีประสิทธิภาพ

อุตสาหกรรมที่เกี่ยวข้อง

- โรงจอดรถอัติโนมัติ

- สิ่งทอ

- วิศวกรรม

- อิเล็กทรอนิกส์

- บรรจุภัณฑ์

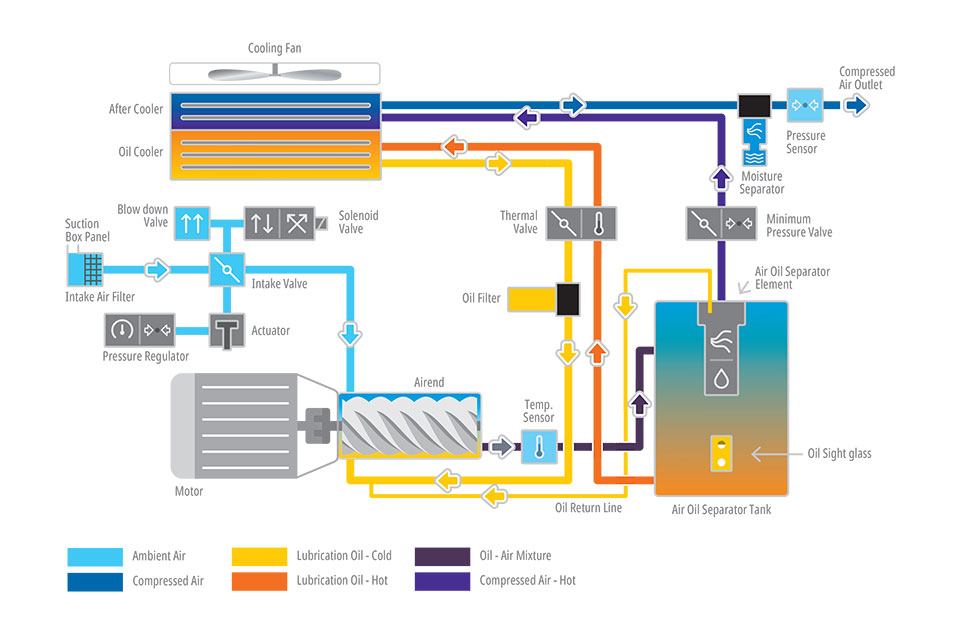

ภาพเครื่องปั๊มลมรุ่น อีจี ขนาด

11 – 75 กำลังวัตต์

รูปภาพผลิตภัณฑ์

ตั้งแต่แผนบริการ เครือข่ายบริการไปจนถึงอะไหล่แท้ของ ELGi สำรวจบริการและอะไหล่ที่หลากหลายของเรา เพื่อค้นหาสิ่งที่คุณต้องการ.

ร้องขอบริการ