ELGi is one of the few compressor companies that design and manufacture oil-free airends. The compressors are engineered to deliver maximum uptime and reliability with in-house oil-free technology. ELGi’s unique eta-V rotor design reduces pressure losses and increases stage efficiencies, leading to an optimised compressed air system.

The optimised component layout of the ELGi OF series machine provides easy serviceability and reduced service time. Incorporating superior safety norms, the compressors have low energy losses and low air outlet temperatures and are highly reliable and compact. ELGi oil-free air compressors have all these advanced features integrated into one simple design that drives maximum reliability and uptime. Choose ELGi and discover the benefits of Oil-Free Electric Air Compressors engineered for superior performance, reliability, and efficiency.

WHY ELGi's OIL-FREE SERIES?

Class 0 oil-free air

Our Oil-Free series produces consistent oil-free air, meeting ISO8573-1 class 0 oil standards. The food-grade coating is applied where air contacts the metal surface inside the compressor, ensuring consistent oil-free air without metal debris. Pipes have special e-coating, which ensures consistently clean and oil-free air, along with optimised rotor clearances, which ensure consistent air delivery.

Indigenously designed and manufactured airends

ELGi is one of the few air compressor companies that design and manufacture oil-free airends. With our in-house oil-free technology, the compressors are engineered to deliver maximum uptime and reliability. ELGi’s unique eta-V rotor design reduces pressure losses and increases stage efficiencies, leading to an optimised compressed air system.

PTFE airend coating for efficiency and long-term reliability

Our airend Rotors and housing are coated with PTFE-based food-grade PP coating to resist corrosion and endure temperatures up to 250 degrees C. This results in optimum long-term performance with no loss in efficiency.

Flexible design allowing for air-cooled and water-cooled requirements

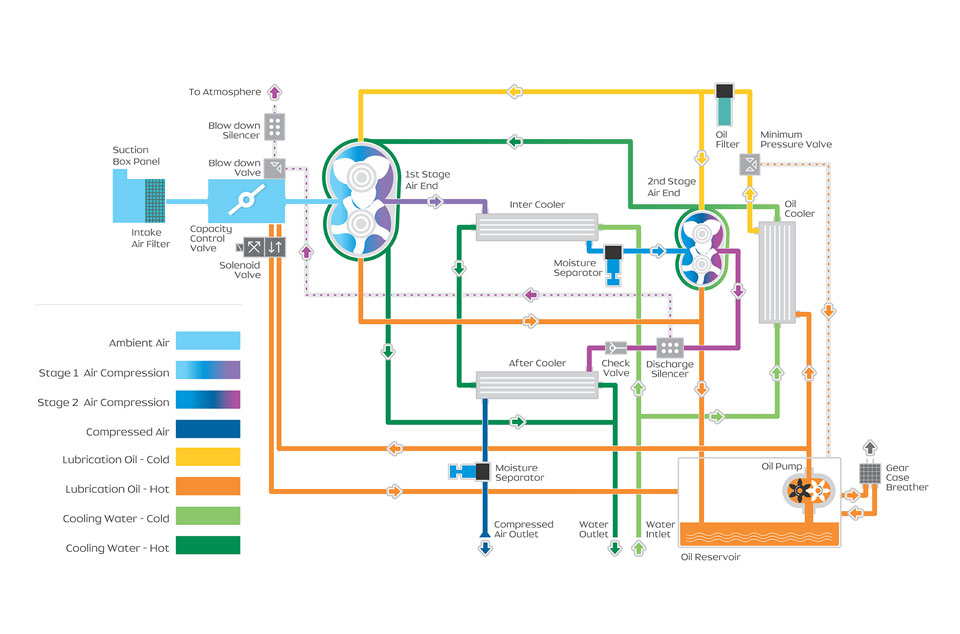

Our Oil-Free series carries Cupronickel coolers with a water-in-tube system, specially designed for a temperature difference of 8 degrees C, having the least fouling factor with the best thermal efficiency.

Best-in-class warranty

ELGi comes with Uptime Assurance, which is all about giving customers peace of mind by offering the industry's leading warranty, which warrants that its product and the components for its products will perform the purpose and function for which they are designed and intended for the periods indicated when used, serviced and maintained in accordance with ELGi's instruction and specification.

Best-in-class maintenance cost

With our Rack and Pinion capacity control system in the Oil-Free series, there is no maintenance required for over one million cycles.

DESIGNED FOR APPLICATIONS

ACROSS INDUSTRIES

Air-Cooled vs Water-Cooled Compressors: ELGi's Guide to Choosing the Right One

One of the most crucial considerations when purchasing an industrial air compressor is whether to go with an air-cooled or water-cooled type. Both have advantages and disadvantages, so the choice depends on your individual requirements and operating environment. ELGi, a renowned manufacturer of air compressors, provides a diverse selection of air-cooled and water-cooled choices to meet your needs.

Air-Cooled Compressors

Air-cooled air compressors are the most common type, utilising a fan and radiator to dissipate heat generated during the compression process. They're:

Simple and easy to maintain: With fewer components than water-cooled systems, air-cooled compressors are less prone to breakdowns and require less maintenance.

Cost-effective: They have a lower initial purchase price and lower operating costs as they don't require water treatment or a dedicated cooling system.

Energy efficient: Though they consume slightly more power than water-cooled models, air-cooled compressors can recover heat loss and utilise it for space heating or other applications.

Water-Cooled Compressors

Water-cooled air compressors use an external liquid coolant loop to extract heat from the compressed air. They offer:

Higher efficiency and performance: Water-cooled air compressors can operate at higher temperatures and pressures, leading to increased efficiency and productivity.

Reduced noise levels: The external cooling system helps minimise noise pollution, making them ideal for sensitive environments.

Compact design: Water-cooled screw compressors can be smaller and more compact than air-cooled models for the same air output.

No matter your industry, The ELGi Two stage oil free air compressors are engineered to meet your specific needs. Discover how we can empower your business and ensure maximum efficiency and cost savings.

Discover the perfect compressor solution for your industry.

FREQUENTLY ASKED QUESTIONS

Oil Free Two Stage Water Cooled

Two Stage Oil Free Air Compressor

From service plans, service networks to Genuine ELGi parts, explore our vast range of services and parts to find exactly what you need.

CONNECT WITH US