ELGi’s EG Series oil-lubricated screw air compressors represent a giant leap in design and performance, with every component designed for reliability and ease of maintenance. The EG series oil-lubricated air compressors come with highly efficient airends equipped with our in-house eta-v profile rotors. ELGi’s each screw compressor is designed and manufactured in compliance with applicable international standards (CE, ASME, UL, and others). The ELGi EG series oil lubricated screw air compressors are available in three variants to suit your needs. These air compressors are equipped with our in-house eta-V profile rotors, making them energy-efficient. The ELGi EG series screw air compressors offer the best-in-class warranty program and operating cost.

The 11-75kW EG series finds application in auto garages, textiles, electronics, engineering, and packaging. The 90-160kW and 200-250kW range is suitable for automotive, cement, paper and pulp, and steel, industries.

WHY ELGi's EG SERIES SCREW COMPRESSOR?

Our EG series has highly efficient airends which are equipped with in-house developed eta-V profile rotors, with 4/5 lobe combination. The unique design of the rotor enables it to run at optimum speed which reduces pressure loss, increases efficiency and in turn ensures energy-efficient compressed air supply for all demanding applications.

Best-in-class maintenance and operating cost

Our EG Series Compressors provide high-quality compressed air in the harshest environmental conditions. Incorporating the next generation technology of ELGi's oil injected screw compressor , they provide a long and trouble-free life at the low operating cost

Lowest oil carryover in the industry

Because of our unique OSBIC process (Oil Separation by Impact and Centrifugal action) in EG Series Compressor it enables efficient separation of air and oil in 3 stages, delivering consistent oil-free air with minimum pressure drop.

Best-in-class warranty program

ELGi air compressors are backed by Uptime Assurance, providing customers with peace of mind. This industry-leading warranty warrants that the products, along with their components, will function as intended when used, serviced, and maintained in line with ELGi's guidelines and specifications for the specified periods.

Outstanding reliability stemming from slow operating speeds and low operating temperatures

Our EG series compressors are designed to perform at extreme temperatures – from cold to hot and from dry to extremely humid conditions.

Operating data and safety measures

Our EG Series compressors are designed and perfected to ensure the highest level of safety for - Pressure regulating valves, High pressure, High temperature, Pressure relief valves, Phase order and single phase

Optional variable speed drives for energy efficiency

Our EG Series compressors have precise rotor clearances for best-in-class energy efficiency, resulting in low operating speeds for long life, low maintenance, and low sound levels. Our in-built Variable Frequency Drives (VFD) match compressor output with demand by varying motor speed, thus reducing the power consumption line with the reduction in demand, which helps in eliminating the frequent load-unload cycle and also the wasted power from the energy bill.

INDUSTRIAL APPLICATIONS OF

OIL LUBRICATED SCREW COMPRESSORS

ELGi’s oil lubricated screw compressors are designed to cater to a wide range of industrial applications. Whether it's manufacturing, construction, or automotive, these electric air compressors offer reliable and consistent compressed air supply. With the ability to maintain high performance levels even in demanding conditions, our electric air compressors are a cornerstone of operational excellence

Auto garages, textiles, engineering, electronics, packaging and many more industries rely on the EG Series for efficiency and precision. These robust compressors deliver unwavering performance, ensuring seamless processes and enhanced productivity.

ELGi’s Electric Screw Compressors redefine industry standards, offering unmatched efficiency and performance. Powered by advanced technology and precision engineering, these oil injected compressors ensure optimum performance while minimising energy consumption.

If you’re searching for the best EG Series compressor on the market, look no further than ELGi.

FREQUENTLY ASKED QUESTIONS

How do ELGi EG Series Lubricated Compressors Work?

ELGi's EG Series compressors are oil lubricated compressors. The oil lubricated screw air compressor ensures smoother operations, reduced wear and tear, and a prolonged lifespan. The oil injected rotary screw compressor technology optimises performance and minimises energy consumption, making it an ideal choice for heavy-duty applications.

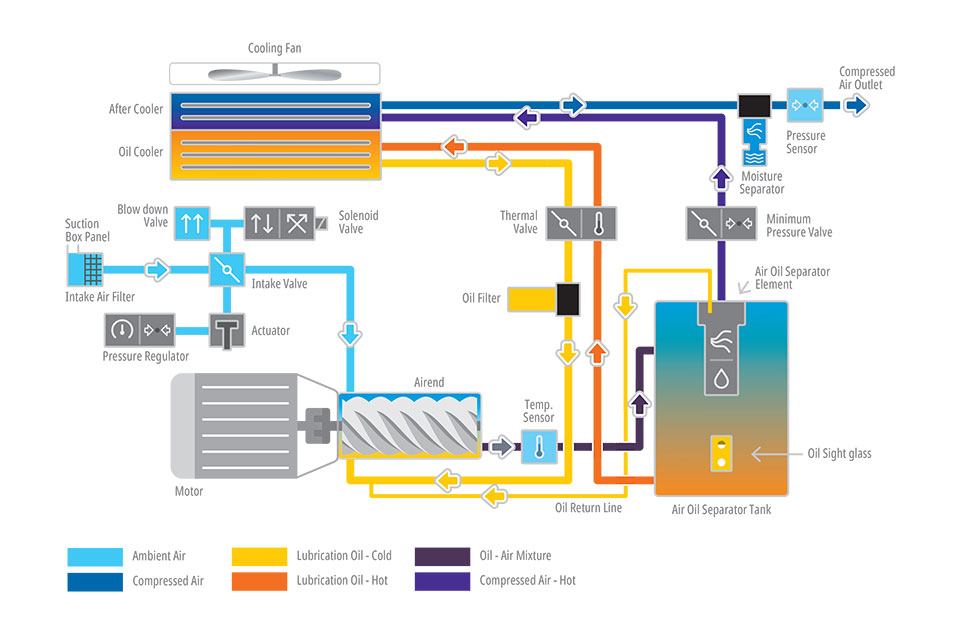

The compressor's inlet filter draws in ambient air to compress within the compression chamber of the oil flooded screw compressor. This chamber consists of male and female rotors with helical lobes that interlock and gradually compress the air. A precisely controlled quantity of lubricating oil is injected into the chamber during this compression process. This oil serves multiple vital functions, including sealing gaps between the rotors, reducing friction, dissipating heat, and contributing to the system’s overall efficiency.

Following compression, the air-oil mixture is directed to an oil separator element, where centrifugal forces facilitate the separation of oil droplets from the compressed air. The separated oil returns to the compressor's oil circuit for reuse, maintaining an efficient closed-loop lubrication process. The purified compressed air, now devoid of contaminants and excess oil, exits the compressor element and undergoes cooling with help of accessories to reduce temperature and moisture content. Stored in an air receiver tank, the cooled and compressed air is then distributed for various applications, powering machinery, pneumatic tools, and numerous industrial processes.

11 – 75 kW EG Series

From service plans, service networks to Genuine ELGi parts, explore our vast range of services and parts to find exactly what you need.

CONNECT WITH US