THE TECHNICAL EDGE TO POWER YOUR BUSINESS

ELGi EG Series screw air compressors are engineered to be energy-efficient compressors to minimise operating costs. The EG Series oil-lubricated rotary screw compressor is equipped with cutting-edge technological features such as ELGi’s proprietary η-V airends, a unique OSBIC oil-separation process, advanced motor and package design, and the next-generation intake valve and cooling systems, which results in a highly energy-efficient compressor and low cost of ownership.

TECHNICAL SPECIFICATIONS

Motor Power

11 kW to 250 kW

Working Pressure

4.5 bar g to 12.5 bar g

Airflow

2.01 m3/min to 43.18 m3/min

BENEFIT FROM INDUSTRY-LEADING ENERGY EFFICIENCY AND SAVINGS

Highly Efficient Proprietary Airend Design

The ELGi EG Series screw air compressors have unique airends, in-house developed η-V profile rotors, and a 4/5 lobe combination. The rotors in the EG Series oil-lubricated rotary compressors are designed to run at low speeds to increase efficiency and life. The unique airend supplies compressed air for all demanding applications while ensuring minimal environmental impact.

Highly Reliable and Efficient Motors

The motors in the EG Series oil-lubricated rotary compressors have a larger core and increased windings to provide better thermal management. Additional fins on the face of the motor with the lowest air block over the frame offer better reliability.

Advanced Package Design

The EG Series electric screw compressors package is configured with subsystems designed to minimise system losses and maximise energy savings. While the design offers easy serviceability, the aesthetically built acoustic enclosure keeps the noise levels in check.

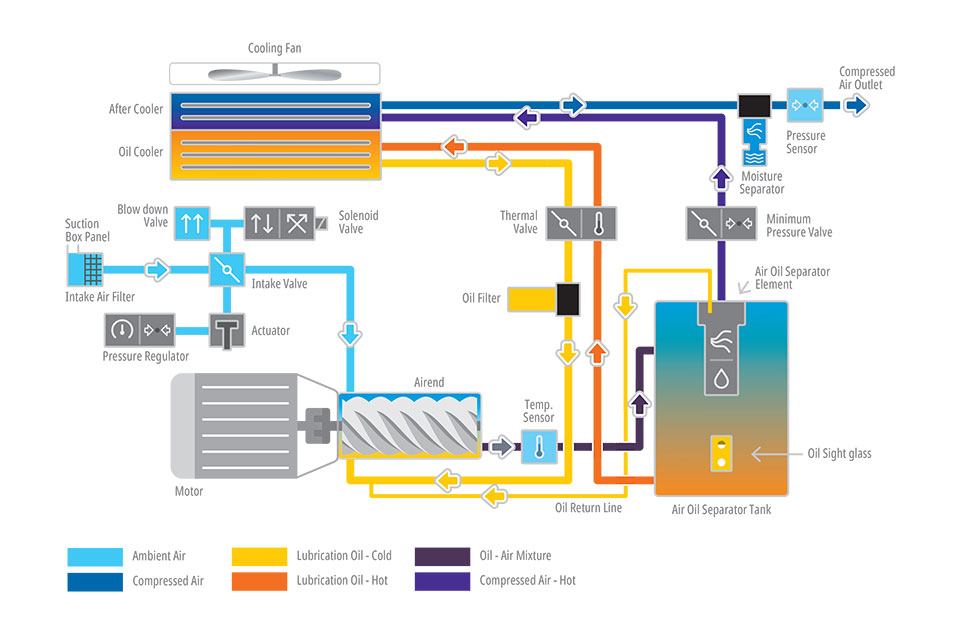

Reduced Starting Load

The new generation intake valve in the EG Series oil-lubricated rotary screw compressor is designed for high efficiency with an integrated blow-down unit, solenoid control, and actuator. The intake valve optimally controls the compressor capacity during start-up, reducing the starting load on the motor.

Low Oil Carryover (1ppm)

ELGi has developed a unique OSBIC process (Oil Separation by Impact and Centrifugal action) to separate air and oil with minimum pressure drop for its oil-lubricated rotary compressors. This process involves removing oil in three stages, delivering consistent low oil carryover in the compressed air, and reducing the oil discharged into the environment. This efficient method also increases the life of the air-oil separation filter and makes the ELGi EG Series screw air compressors environmentally-friendly.

Highly Efficient cooling System

The advanced cooling system in the EG Series screw compressors comes with optimal fans and a large cooler surface area that offers superior cooling performance. The integrated fan motor uses significantly low power and maintains an optimal temperature range of oil, thereby increasing the life of the parts. This intelligent cooling system keeps the discharged compressed air temperature low, easing the load on the downstream equipment. Split coolers are standard on our EG Series lubricated compressors, increasing the unit's reliability and facilitating easy maintenance.

Integrated Moisture Separator

The EG Series lubricated air compressors have a centrifugal-type moisture separator with an automatic drain that comes as a part of the package at no extra cost. The separator removes over 99% of bulk water from the compressed air, resulting in a corrosion-free, longer life of the complete compressed air system. The advanced moisture separator also reduces the load on the dryer.

Advanced Neuron III Controller

The advanced Neuron III Controller in the EG Series oil-lubricated rotary screw air compressors allows remote equipment monitoring and provides operational reports. It also reminds the user to maintain the compressor periodically and alerts them of any issues.

Extensive Range from 11 – 250kW

The ELGi EG Series is a game-changer in compressed air solutions with an extensive range spanning from 11kW to 250kW. With this wide spectrum of options, customers enjoy the unmatched flexibility to tailor their compressed air systems precisely to their unique needs, ensuring optimal efficiency and cost savings. Whether you're a small business or an industrial giant, the EG Series offers the perfect solution, empowering you to meet your compressed air requirements with precision and excellence.

ENSURE COMPLETE PEACE OF MIND WITH SUPERIOR WARRANTY

The EG Series screw compressors provide our European customers with an industry-leading warranty of 10 years on the air end with no limitation on running hours, a 5-year package warranty, a 3-year warranty on VFD, and one year on rubber, electrical, and plastic parts.

*Terms and conditions apply

Get Expert Guidance and Personalized Solutions

DESIGNED FOR APPLICATIONS

ACROSS INDUSTRIES

The EG Series oil-lubricated rotary compressors are the backbone of various industries, ensuring optimal performance and efficiency. Our compressors cater to a wide range of applications, making them the preferred choice for businesses across different sectors:

OVER 2 MILLION SUCCESSFUL COMPRESSED AIR INSTALLATIONS WORLDWIDE

WHY DO CUSTOMERS PREFER TO BUY EG SERIES ROTARY SCREW COMPRESSORS?

No matter your industry, The EG Series rotary screw air compressors are engineered to meet your specific needs. Discover how we can empower your business and ensure maximum efficiency and cost savings.

Explore the ideal compressor solution for your industry.

Maximise Your EG Series Performance with ELGi Accessories and Genuine Parts!

The EG Series is backed by a wide range of after-sales products and services designed to maximise customer value. ELGi Airmate Accessories help remove water and other impurities and conserve heat. By minimising pressure losses, preventing equipment damage, and conserving energy, our air compressors can maximise savings for your business and make them environmentally friendly.

ELGi Genuine Spare and Service

Genuine spares and services from ELGi help to avoid unexpected compressor failures and the risk of subsequent damage to other vital compressor components. ELGi spares are designed, manufactured, and checked for quality to meet the standards of a new ELGi compressor.

ELGi Air Audit

ELGi air audit program helps improve the compressors' performance by identifying the areas of wastage in the system. ELGi air audit services are offered for generation, distribution, and demand-side systems.

ELGi Air~Alert

Air~Alert is ELGi’s own IoT-enabling device that upgrades your compressors to Industry 4.0. Air~Alert allows users to track their air compressor’s performance 24/7, remotely, from anywhere in the world.

FREQUENTLY ASKED QUESTIONS ABOUT THE EG SERIES

From service plans, service networks to Genuine ELGi parts, explore our vast range of services and parts to find exactly what you need.

CONNECT WITH US