ELGi’s cutting-edge 200-250 kW EG Series Electric Lubricated Screw Air Compressors are designed for peak performance and unparalleled efficiency and reliability in industrial applications. They offer steady and high-quality compressed air, fulfilling the needs of heavy-duty applications. The sturdy construction ensures durability, reducing downtime and maintenance expenses. These compressors are environment friendly, and offer energy-efficient operations that lower the carbon footprint. The user-friendly interface makes operation easier, and unique features improve safety and longevity. Increase your production and enjoy smooth operations with our 200-250 kW EG Series Electric Lubricated Screw Air Compressors.

WHY ELGi's EG SERIES SCREW AIR COMPRESSOR?

Best-in-class energy efficiency

Our EG series has highly efficient air ends, equipped with in-house developed eta-V profile rotors with a 4/5 lobe combination. Because of the unique design of the rotors, it runs at optimum speeds, which reduces pressure losses and increases efficiencies and, in turn, ensures energy-efficient compressed air supply for all demanding applications.

Best-in-class maintenance and operating cost

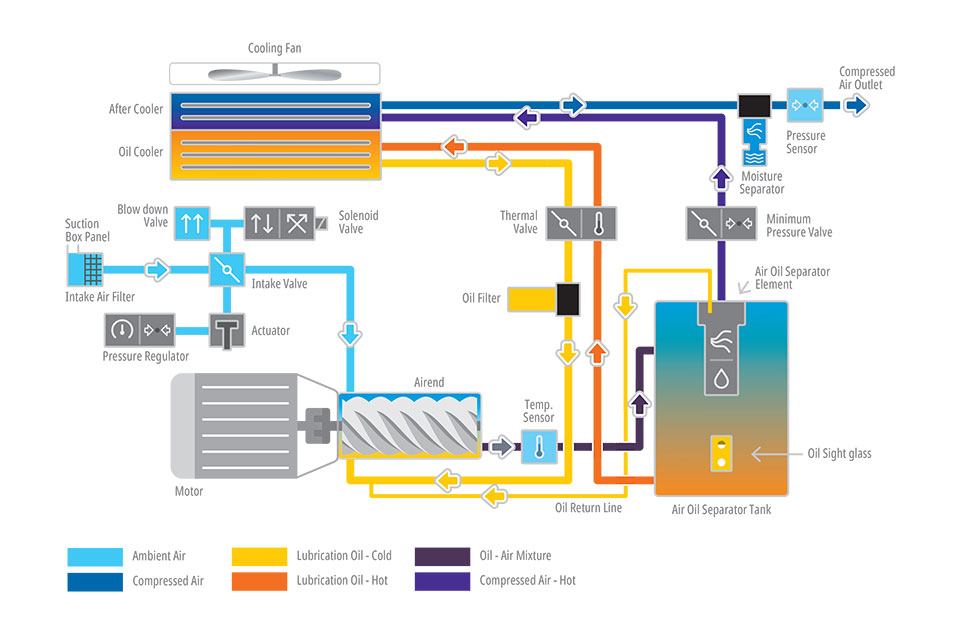

Our EG Series electric lubricated screw air compressors provide high-quality compressed air in the harshest environment conditions. ELGi's in-house designed and manufactured airend of the oil-injected screw compressor enables a long and trouble-free life at a low operating cost.

Low oil carryover

Because of our unique OSBIC process (Oil Separation by Impact and Centrifugal action) in EG Series electric screw compressor, it enables efficient separation of air and oil in 3 stages, delivering consistent oil-free air with minimum pressure drop.

Best-in-class warranty program

ELGi compressors come with Uptime Assurance, which is all about giving customers peace of mind by offering the industry's leading warranty, which warrants that its products and the components for its products will perform the purpose and function for which they are designed and intended for the periods indicated when used, serviced and maintained in accordance with ELGi's instruction and specification.

Outstanding reliability stemming from low operating speeds and low operating temperatures

Our EG series compressors are designed to perform at extreme temperatures – from cold to hot and from dry to extremely humid conditions.

Optional variable speed drives for energy efficiency

Our EG Series compressors have precise rotor clearances for best-in-class energy efficiency, resulting in low operating speeds for long life, low maintenance and low sound level. Our in-built Variable Frequency Drives (VFD) match compressor output with demand by varying motor speed; thus, the power consumption reduces in line with the reduction in demand, which helps in eliminating the frequent load-unload cycle and also the wasted power from the energy bill.

Operating data and safety measures

Our EG Series oil-lubricated rotary screw air compressors are designed to ensure the highest level of safety for - Pressure regulating valve, High pressure, High temperature, Pressure relief valve, Phase order and single phase.

INDUSTRIAL APPLICATIONS OF

OIL LUBRICATED SCREW COMPRESSORS

ELGii offers specialized EG 200 - 250 kW compressors suitable for various industries to enhance operational efficiency and productivity.

If you’re searching for the best EG Series compressor on the market, look no further than ELGi.

FREQUENTLY ASKED QUESTIONS

200 – 250 kW EG Series

From service plans, service networks to Genuine ELGi parts, explore our vast range of services and parts to find exactly what you need.

CONNECT WITH US